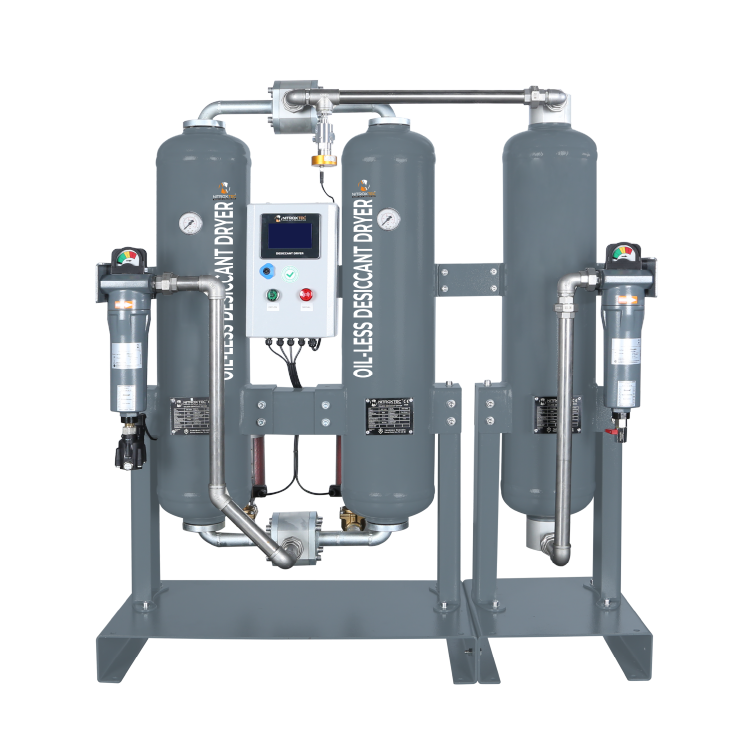

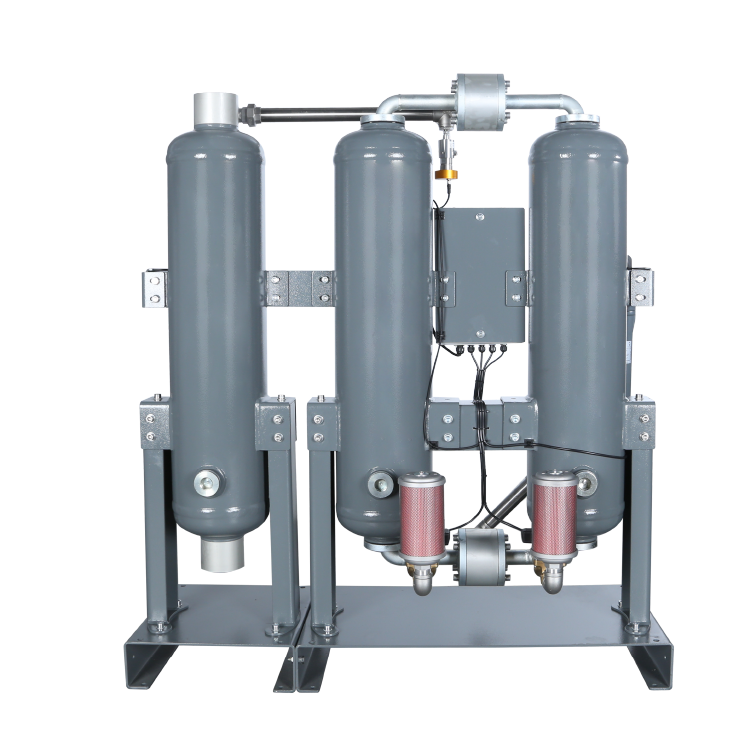

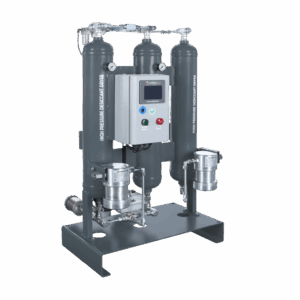

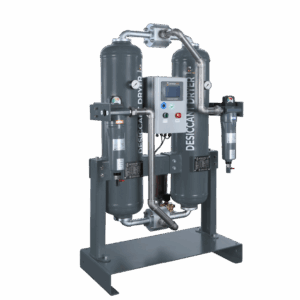

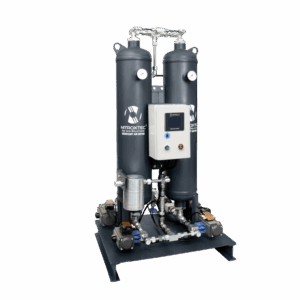

Nitroxtec Oilless Desiccant Dryers

Oil-Free, Ultra-Dry Air for Critical Applications

Nitroxtec Oilless Desiccant Dryers are designed to deliver ultra-clean, dry, and oil-free compressed air, meeting the demands of high-precision industries like pharmaceuticals, electronics, food processing, and clean manufacturing. With a combination of high-performance desiccant drying and activated carbon filtration, the system achieves ISO 8573-1:2010 Class 1 for oil and Class 2 for water—ensuring the highest levels of air purity.

These dryers provide dew points as low as -40 °C and outlet oil content as low as 0.003 mg/m³. Operating 24/7 with fully automatic PLC control, they regenerate desiccant efficiently while consuming only 10–15% purge air, helping to reduce operational costs. The system also features a zero air loss condensate drain, ensuring maximum compressed air utilization.

Key Features

| Feature | Benefit |

|---|---|

| 0.003 mg/m³ Outlet Oil Content | Ultra-clean compressed air exceeds standard industry requirements. |

| Dew Point Down to -40 °C | Prevents condensation and corrosion, ensuring system integrity. |

| Purge Air Loss 10–15% | Efficient regeneration minimizes energy waste and operational costs. |

| Integrated Desiccant + Activated Carbon System | Dual-stage removal of water vapor and oil vapor. |

| Zero Air Loss Condensate Drain | Prevents waste and protects overall system efficiency. |

| Automatic PLC Control | Manages regeneration, dew point, and system logic in real time. |

| Optional Dew Point Sensor | Enables adaptive operation and energy savings. |

| Color Touchscreen Display | Provides real-time monitoring and alarm notifications. |

| 24/7 Continuous Operation | Stable and reliable for around-the-clock applications. |

| Max. Operating Pressure: 20 bar | Suitable for demanding industrial compressed air systems. |

Working Principle

The system operates in two filtration phases:

-

Moisture Removal – Compressed air passes through a tower filled with activated alumina, which absorbs water vapor to achieve a dew point of -40 °C.

-

Oil Vapor Removal – Air is then routed through an activated carbon module that captures residual oil and hydrocarbon vapors down to 0.003 mg/m³.

The desiccant is regenerated automatically using purge air, which accounts for 10–15% of the total air volume, and the process is managed by a PLC for precision timing, dew point control, and energy-saving modes. The system runs continuously, with the towers alternating between drying and regeneration.

Why Choose Nitroxtec Oilless Desiccant Dryers?

• Meets ISO 8573-1:2010 Class 1 Oil & Class 2 Moisture

• Efficient Operation – Only 10–15% purge air loss during regeneration

• Zero-Loss Drain System – Prevents unnecessary compressed air discharge

• Long Desiccant Life – High-quality alumina and carbon reduce replacement frequency

• Remote Monitoring Options – Modbus-ready for integration with factory systems

• Durable & Industrial-Grade – Designed for non-stop use in demanding environments

Applications

• Pharmaceuticals & Cleanrooms – Oil- and moisture-free air for sterile processes

• Electronics Manufacturing – Protects sensitive components from contamination

• Food & Beverage – Compliant compressed air for packaging and processing lines

• Paint & Automotive Finishing – Ensures surface quality and prevents defects

• Precision Manufacturing – Clean, dry air for CNC and pneumatic machinery

Uncompromising Air Quality. Unmatched Efficiency.

With Nitroxtec Oilless Desiccant Dryers, you gain full control over air quality, energy efficiency, and long-term performance. Designed with high-purity filtration, smart automation, and low purge loss operation, these systems ensure that your critical processes remain protected, precise, and compliant.