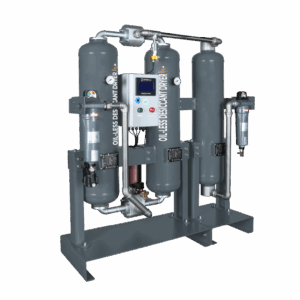

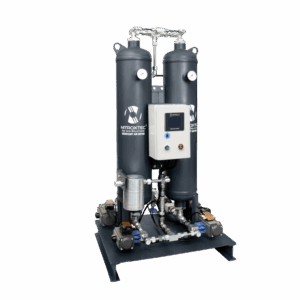

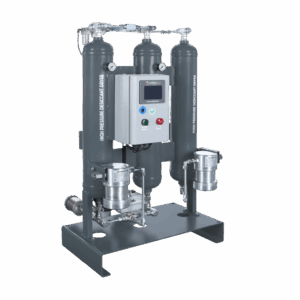

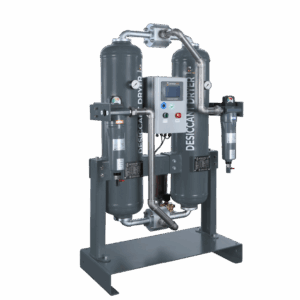

Nitroxtec Modular Type Oilless Desiccant Dryers

Modular, Oil-Free, and Ultra-Dry Air for Demanding Applications

Nitroxtec Modular Type Oilless Desiccant Dryers are engineered for applications that require exceptionally clean, oil- and moisture-free compressed air. Combining desiccant drying with activated carbon filtration, the system effectively removes both water vapor and oil vapors, achieving dew points down to –40 °C or –70 °C and meeting ISO 8573-1:2010 Class 1 for oil and Class 2 for moisture.

The system’s modular, weld-free design eliminates the need for welding certification or testing—making installation easier and maintenance lower. With a dual-tower adsorption system, the dryer ensures uninterrupted operation by alternating between drying and regenerating cycles using 10–15% purge air.

Key Features

| Feature | Benefit |

|---|---|

| Oil Content: as low as 0.003 mg/m³ | Delivers oil-free air for sensitive production environments. |

| Dew Point Options: –40 °C or –70 °C | Tailored moisture control to meet specific industry needs. |

| Modular, Weld-Free Design | No welding test required—reduces setup time and lowers maintenance. |

| Dual-Tower Adsorption System | Continuous operation with automatic regeneration and tower switching. |

| Integrated Activated Carbon + Desiccant Media | Effectively removes both moisture and oil vapors. |

| Low Purge Air Loss (10–15%) | Efficient regeneration reduces air consumption and operating costs. |

| Zero-Loss Condensate Drain | Conserves compressed air while maintaining clean system drainage. |

| Electronic Control Panel & Optional Dew Point Sensor | Real-time monitoring with energy-saving logic. |

| 24/7 Operation | Designed for non-stop industrial use. |

| ISO 8573-1:2010 Compliance | Meets Class 1 oil and Class 2 moisture air quality standards. |

Working Principle

This adsorption dryer uses two towers filled with high-efficiency desiccant (such as activated alumina). As moist compressed air enters the system, it passes through one tower where the desiccant adsorbs moisture. The partially purified air then moves through an activated carbon stage, where it is further cleaned of oil vapor and hydrocarbons, reaching an oil content as low as 0.003 mg/m³.

Meanwhile, a small portion of the dried air (10–15% purge) regenerates the second tower. The system automatically alternates between towers to provide a continuous flow of clean, dry, oil-free compressed air.

Why Choose Nitroxtec Modular Type Oilless Desiccant Dryers?

• No Welding Test Required – Weld-free construction simplifies installation and service

• Oil & Moisture Removal in One System – Dual-stage design for consistent air quality

• Dew Point Flexibility – Choose –40 °C or –70 °C depending on your process requirements

• Low Energy Use – Efficient regeneration reduces air and power consumption

• Modular & Scalable – Designed to grow with your facility’s air demand

• Meets ISO Class 1 Oil / Class 2 Water – Suitable for the most demanding applications

Applications

• Pharmaceuticals & Cleanrooms

– Maintains contamination-free environments with ultra-dry, oil-free air

• Electronics & PCB Manufacturing

– Protects components from static discharge, corrosion, and moisture

• Food & Beverage Processing

– Delivers clean, hygienic compressed air for packaging and bottling systems

• Laser Cutting & CNC Systems

– Prevents oxidation, improves cut quality, and extends equipment life

• Paint & Automotive Finishing

– Ensures flawless surface coating and prevents paint defects

• Industrial Pneumatics & Robotics

– Increases system reliability and reduces wear in air-powered equipment

Oil-Free. Weld-Free. Worry-Free.

Nitroxtec Modular Type Oilless Desiccant Dryers deliver stable, high-purity compressed air with simplified installation, reduced energy consumption, and long-term reliability. With modular flexibility and certification-free weld-free construction, they’re the ideal choice for industries where air quality is mission-critical.