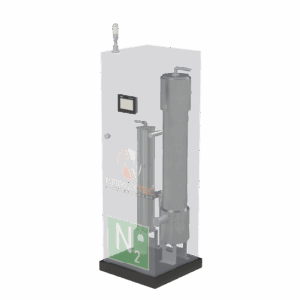

Nitroxtec Modular Nitrogen Generators

Compact, Scalable, and Energy-Efficient On-Site Nitrogen Production

Nitroxtec Modular Nitrogen Generators offer an advanced solution for producing high-purity nitrogen directly at your facility. Designed with a compact footprint, modular architecture, and optimized energy efficiency, they eliminate the need for gas cylinders or liquid nitrogen deliveries. Using Pressure Swing Adsorption (PSA) technology, these systems provide continuous, ultra-clean nitrogen tailored to meet the demands of a wide range of industrial applications.

Key Features

Modular & Scalable Architecture

• Easily expandable design allows you to increase capacity without replacing the entire system—ideal for growing operations.

High Nitrogen Purity – Up to 99.9999%

• Adjustable purity levels to meet even the most sensitive and critical industrial requirements.

Energy-Efficient Operation

• Low air-to-nitrogen ratio reduces compressed air usage and energy consumption, resulting in lower operational costs.

Compact & Space-Saving Design

• Ideal for space-constrained environments without compromising performance or service accessibility.

Weld-Free Construction – No Welding Test Required

• The system is built entirely without welded joints, so no welding certification or welding test is needed.

• This reduces risk of structural fatigue, ensures easier maintenance access, and lowers long-term service costs.

Reliable 24/7 Nitrogen Supply

• Uninterrupted production guarantees operational continuity and independence from third-party deliveries.

Quick Installation & Plug-and-Play Start-Up

• Fast commissioning ensures smooth integration into existing production lines with minimal disruption.

ISO 8573-1:2010 Class 2.4.1 Air Quality Compliance

• System operates with compressed air filtered to strict standards—ensuring protection of carbon molecular sieve (CMS) media and long-term purity stability.

Why Choose Nitroxtec Modular Nitrogen Generators?

• Custom-Configured Systems – Tailored to your specific flow rate, pressure, and purity requirements.

• Weld-Free Construction – No welding test required, with fewer leak points and lower maintenance costs.

• Lower Total Cost of Ownership – Reduced energy use, minimal maintenance, and elimination of nitrogen delivery costs.

• Sustainability Focused – Lowers your carbon footprint by producing nitrogen on-site and eliminating transport emissions.

• Future-Proof Design – Modular configuration ensures seamless capacity expansion as your production needs evolve.

• Built for Reliability – ISO-compliant air quality and solid mechanical integrity for long-term durability.

Typical Applications

• Food & Beverage – Modified Atmosphere Packaging (MAP) to extend product shelf life and preserve freshness.

• Electronics Manufacturing – Ultra-clean nitrogen for soldering, reflow ovens, and sensitive component handling.

• Pharmaceuticals & Laboratories – Inert environments for contamination control and product integrity.

• Laser Cutting – Clean, high-purity nitrogen ensures precision cutting with oxide-free edges.

• Chemical & Industrial Processing – For blanketing, purging, and inerting in critical production environments.

Customizable Solutions for Your Industry

At Nitroxtec, we understand that each industry has specific needs. That’s why our engineering team works closely with you to develop nitrogen systems that integrate perfectly into your operation—delivering purity, reliability, and performance every step of the way. Our modular, weld-free designs simplify installation and long-term upkeep, making Nitroxtec the smart choice for efficiency, safety, and scalability.