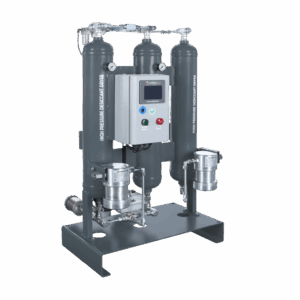

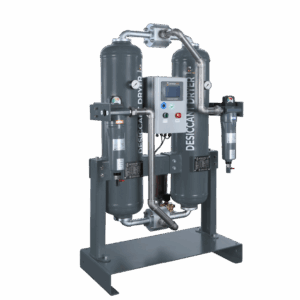

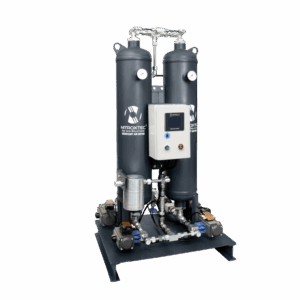

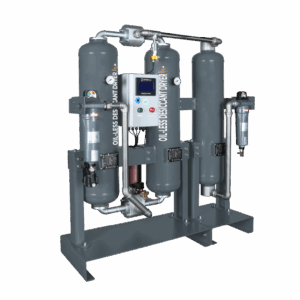

Nitroxtec Modular Type Desiccant Dryers

Modular, Maintenance-Friendly Solutions for Ultra-Dry Air

Nitroxtec Modular Type Desiccant Dryers provide an efficient and reliable solution for producing ultra-dry compressed air, ensuring maximum equipment protection and product quality in moisture-sensitive applications. Based on Pressure Swing Adsorption (PSA) technology, the system uses high-performance desiccant materials such as activated alumina, silica gel, or molecular sieve to reduce moisture content and achieve a consistent dew point of –40 °C or –70 °C, depending on your operational needs.

Thanks to their modular and weld-free design, these dryers offer easy installation, scalability, and low maintenance costs—without requiring any welding certification or welding test. The two-tower system ensures uninterrupted operation by alternating between drying and regeneration cycles automatically.

Key Features

| Feature | Benefit |

|---|---|

| Dew Point Options: –40 °C or –70 °C | Selected based on your process requirements for optimal moisture control. |

| No Welding Test Required | Weld-free frame eliminates the need for certification and simplifies service. |

| Low Maintenance Structure | Fewer failure points and easier access reduce total ownership cost. |

| Modular Design | Easily expandable or reconfigured to meet future air flow demand. |

| Wide Capacity Range | Covers air flow rates from small production lines to large industrial systems. |

| Dual-Tower PSA Operation | Ensures 24/7 drying with automatic regeneration and seamless switchover. |

| High-Efficiency Desiccant Media | Long-lasting adsorption using silica gel, molecular sieve, or activated alumina. |

| Optional Dew Point Monitoring | Real-time dew point tracking for consistent output quality. |

| Electronic Control Panel | User-friendly interface with alarms and performance feedback. |

| ISO 8573-1:2010 Class 2 Compliance | Guarantees air purity required for high-precision operations. |

Working Principle

Compressed air enters one of two desiccant-filled towers, where moisture is adsorbed by high-efficiency materials such as activated alumina or silica gel. While one tower is in drying mode, the second tower regenerates by purging a small portion of the dry air. The system automatically alternates between towers to ensure uninterrupted operation.

The regeneration cycle is optimized to maintain energy efficiency, and customers can choose between –40 °C or –70 °C dew point performance, depending on the application and required air dryness.

Why Choose Nitroxtec Modular Type Desiccant Dryers?

• No Welding Test Required – Weld-free structure reduces approval processes and simplifies maintenance

• Customizable Dew Point Performance – Choose between –40 °C or –70 °C based on your system’s sensitivity

• Low Operating Costs – Efficient purge cycles and long desiccant life reduce total cost of ownership

• Modular & Scalable – Easily adapt to growing production needs without replacing core equipment

• Continuous 24/7 Operation – Reliable PSA process ensures zero downtime

• Built for Industrial Demands – Compliant with ISO standards and engineered for durability

Applications

• Pharmaceutical Production – Protects cleanroom and packaging operations from moisture

• Food & Beverage Processing – Ensures packaging integrity and hygiene

• Electronics & PCB Manufacturing – Prevents corrosion, short circuits, and contamination

• Precision Machinery & Pneumatics – Ensures long-term reliability and performance

• General Industrial Compressed Air Systems – Prevents condensation and extends equipment life

Weld-Free. Worry-Free. Always Dry.

Nitroxtec Modular Type Desiccant Dryers are built for demanding environments that require moisture-free, ultra-clean compressed air. With their modular design, zero welding requirements, and dew point flexibility, they are the ideal choice for efficient, scalable, and reliable compressed air drying.