Nitroxtec Membrane Nitrogen Generators

Compact. Quiet. On-Demand Nitrogen Generation.

Nitroxtec Membrane Nitrogen Generators are engineered to deliver cost-effective, high-purity nitrogen directly from compressed air—without the need for gas cylinders or complex logistics. Utilizing hollow fiber membrane separation technology, the system separates nitrogen from oxygen and water vapor molecules, providing a continuous nitrogen flow that meets a variety of industrial demands.

The system operates quietly and efficiently, with minimal footprint and zero moving parts, making it especially suitable for environments requiring clean, dry, and maintenance-free nitrogen—such as laboratories, medical facilities, food processing, electronics, and marine industries.

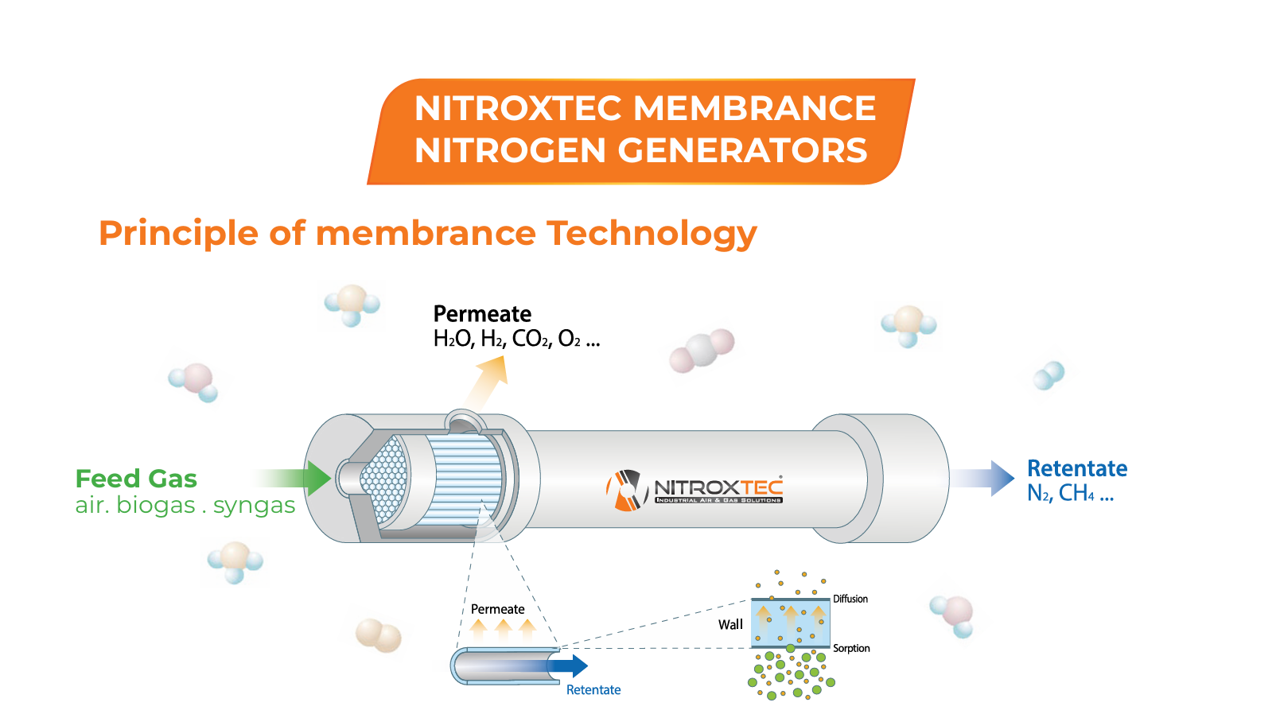

How Membrane Technology Works

The membrane module consists of bundles of hollow fiber membranes made from high-performance polymers. Compressed air is introduced into these fibers. Due to the difference in permeation speeds of various gases:

-

Oxygen, CO₂, and water vapor permeate through the fiber wall more quickly

-

Nitrogen travels down the length of the fiber and is collected at the outlet

This results in a reliable nitrogen stream at controlled purity levels, based on the design and flow rate.

Key Features

| Feature | Benefit |

|---|---|

| Hollow Fiber Membrane Separation | Efficient nitrogen extraction using selective gas permeability |

| Purity Up to 99.5% | Adjustable nitrogen concentration based on application needs |

| Silent Operation | No compressor noise or mechanical vibration |

| Maintenance-Free Design | No moving parts, no periodic component replacement |

| Compact & Lightweight | Easy to install and relocate—ideal for space-constrained environments |

| Quick Startup | Instant nitrogen production, no warm-up time |

| Low Energy Consumption | Reduced operating cost compared to traditional nitrogen sources |

| Environmentally Friendly | Eliminates cylinder transport and storage risk |

| Integrated System Option | Can be combined with air compressors, filters, and dryers for plug & play |

Why Choose Nitroxtec Membrane Nitrogen Generators?

-

Energy-Efficient – Optimized for minimal air consumption and maximum nitrogen yield

-

Flexible Performance – Choose purity levels from 95% to 99.5% depending on your process

-

No Downtime – Continuous 24/7 nitrogen production with zero maintenance required

-

Clean & Dry Output – Ideal for applications where oil, moisture, and particle-free gas is essential

-

Low TCO – No replacement parts, no service contracts, no hassle

Applications

-

Food Packaging – Modified Atmosphere Packaging (MAP) to increase shelf life

-

Electronics & SMT Assembly – Prevent oxidation during soldering and storage

-

Pharmaceuticals & Labs – Stable nitrogen for analytical instruments and sample protection

-

Beverage & Wine Industries – Inerting and bottling processes

-

Marine & Offshore – Nitrogen blanketing and explosion protection

-

Oil & Gas – Pipeline purging and tank blanketing in hazardous areas

Simplicity Meets Innovation.

With Nitroxtec Membrane Nitrogen Generators, you get a quiet, efficient, and flexible nitrogen solution designed for modern industries. Whether you need nitrogen for packaging, lab equipment, or process protection, Nitroxtec provides the reliability and performance you expect—without compromise.