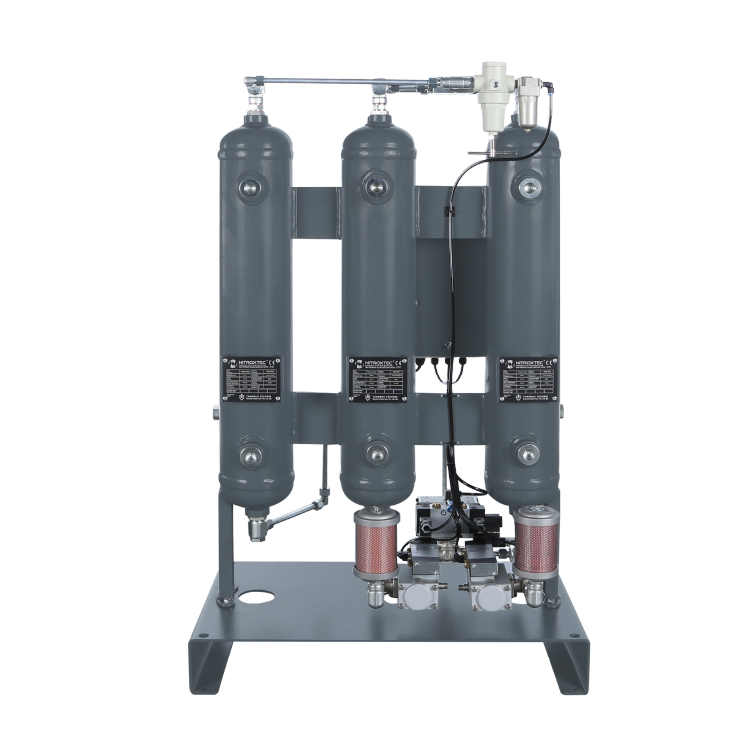

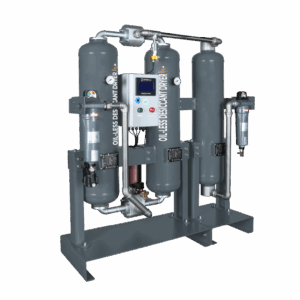

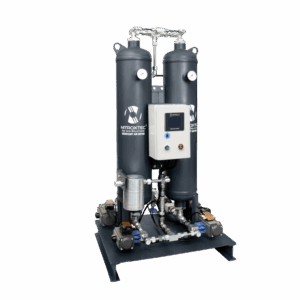

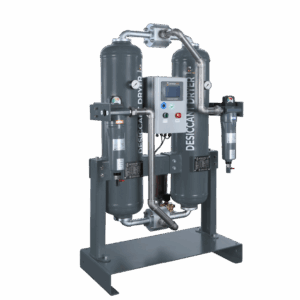

Nitroxtec High Pressure Oilless Desiccant Dryers

Ultra-Clean Air, Even at 300 Bar

Nitroxtec High Pressure Oilless Desiccant Dryers are engineered for high-pressure air systems, offering reliable performance at operating pressures from 40 to 300 bar. Designed for industries where air purity and pressure integrity are critical, these dryers remove both moisture and oil vapors using a dual-stage process: high-efficiency desiccant adsorption followed by activated carbon filtration.

Achieving dew points as low as –40 °C and oil content down to 0.003 mg/m³, they meet strict ISO 8573-1:2010 Class 1 for oil and Class 2 for water standards. Built with high-pressure-rated vessels and components, the system is ideal for PET bottle production, aerospace applications, laser cutting at 40–300 bar, and defense industries.

Key Features

| Feature | Benefit |

|---|---|

| Pressure Range: 40–300 bar | Robust construction for high-pressure industrial use. |

| Oil Content: as low as 0.003 mg/m³ | Ensures clean, contamination-free compressed air. |

| Dew Point Down to –40 °C | Prevents condensation and corrosion in downstream systems. |

| Integrated Desiccant + Activated Carbon System | Dual-stage drying and oil vapor removal. |

| Low Purge Air Consumption (5–10%) | Optimized for efficiency at high pressures. |

| Zero Air Loss Condensate Drain | Prevents compressed air waste, increasing system efficiency. |

| Fully Automatic PLC Control | Smart cycle management, alarms, and performance optimization. |

| Modbus / Remote Monitoring Ready | Seamless integration into industrial control systems. |

| Heavy-Duty Design | Thick-wall vessels, high-grade valves, and safety reliefs for high pressure. |

| ISO 8573-1:2010 Compliant | Class 1 for oil / Class 2 for water air quality certification. |

Working Principle

Compressed air enters the system and flows through a desiccant-filled vessel where moisture is adsorbed. The air then passes through an activated carbon stage, which eliminates residual oil vapors to ensure ultra-clean output. While one tower is in drying mode, the second regenerates using 10–15% purge air. This alternating cycle allows for uninterrupted, 24/7 operation, even at high pressures. The system is managed by a PLC-based control panel that monitors dew point, regeneration timing, and system performance.

Why Choose Nitroxtec High Pressure Oilless Desiccant Dryers?

• Rated for Up to 300 Bar – Built with reinforced steel and high-pressure safety in mind

• Oil-Free, Ultra-Dry Output – Suitable for the most sensitive applications

• Compact & Reliable Design – Space-saving footprint with robust frame

• Low Purge Air Requirement – Helps reduce total compressed air demand

• Long Desiccant Life – Engineered with high-quality activated alumina and carbon media

• Continuous Duty Cycle – No downtime with dual-tower regeneration

• Zero-Loss Drains – Air-saving condensate handling

• Modular Expansion – Easily scale capacity with demand

Typical Applications

• Laser Cutting Systems (16–40 bar and above)

– Ensures moisture- and oil-free cutting air for clean, oxidation-free edges

• PET Bottle Blowing (40–300 bar)

– Delivers dry, oil-free air essential for bottle forming and food-safe packaging

• Defense & Military Systems

– Compressed air for missile launch systems, breathing air, and field applications

• Aerospace & Aviation Support

– High-pressure tool operation, purging, and component cleaning

• Automotive Components & Testing

– High-purity compressed air for high-pressure testing lines

• Specialty Manufacturing

– Any process requiring ultra-pure compressed air at elevated pressures

Built for Pressure. Powered by Precision.

Nitroxtec High Pressure Oilless Desiccant Dryers offer a powerful combination of air purity, pressure durability, and system intelligence. With ISO-compliant performance, energy-efficient purge cycles, and rugged design, they ensure your operations run reliably—no matter how high the pressure.