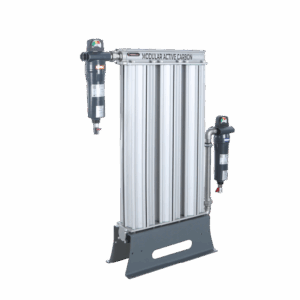

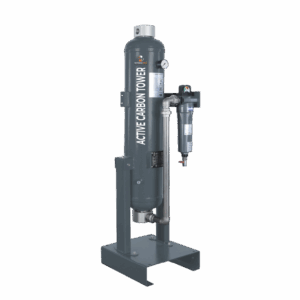

High Pressure Activated Carbon Tower Filters

Oil-Free, Odor-Free Filtration — Built for 40–300 Bar Systems

Nitroxtec High Pressure Activated Carbon Tower Filters are engineered to deliver ultra-clean, oil vapor-free, and odor-free compressed air in demanding high-pressure environments ranging from 40 to 300 bar. Using premium-grade activated carbon and a precision-engineered flow distribution system, these filters ensure residual oil vapor content ≤ 0.003 mg/m³, fully compliant with ISO 8573-1:2010 Class 1 air purity standards.

They are the ideal solution for critical applications such as breathing air, high-end laser cutting, food packaging, electronics, and pharmaceutical manufacturing—where both pressure and air purity cannot be compromised.

What is Activated Carbon?

Activated carbon is a porous, adsorbent material that captures oil vapors, organic compounds, and odors from compressed air. As air passes through the high-pressure-rated carbon bed, hydrocarbons and impurities adhere to the surface of the carbon granules, leaving clean, odorless, and oil-free air at the outlet.

Nitroxtec towers are designed with reinforced vessels, high-quality pre-filtration, and optimized diffusers that evenly distribute air, maximizing adsorption efficiency under high-pressure conditions.

Key Features

| Feature | Benefit |

|---|---|

| For 40–300 Bar Systems | Specifically designed and tested for high-pressure compressed air applications. |

| Residual Oil Vapor ≤ 0.003 mg/m³ | Achieves ISO 8573-1:2010 Class 1 oil purity standards. |

| German-Origin Activated Carbon | Superior adsorption of oil vapor, hydrocarbons, and odors. |

| Heavy-Duty Vessel Design | Pressure-rated housing ensures long-term safety and performance. |

| Integrated Pre-Filtration | Protects the carbon bed from bulk oil and particles. |

| Optimized Diffuser Technology | Ensures uniform airflow across the carbon bed for maximum efficiency. |

| Silenced Outlet | Reduces exhaust noise in high-pressure air systems. |

| Automatic Condensate Drain | Removes collected water and oil efficiently under pressure. |

| Optional Oil Indicator | Monitors saturation level of the carbon media for proactive maintenance. |

| Custom Configuration | Flow rate, port size, and pressure class tailored to application needs. |

Working Principle

Compressed air enters the high-pressure carbon tower through a pre-filtration stage that removes large oil droplets and solid particles. It then passes through a pressurized activated carbon bed, where oil vapors and odor-causing hydrocarbons are adsorbed. The optimized diffuser system ensures uniform air distribution across the bed.

Clean, high-purity air exits the system through a silencer-equipped outlet, while the automatic drain valve removes liquid condensate safely without depressurization.

Why Choose Nitroxtec High Pressure Carbon Tower Filters?

-

Built for 40–300 Bar – Fully engineered for high-pressure applications

-

ISO Class 1 Oil Purity – Delivers residual oil vapor ≤ 0.003 mg/m³

-

Efficient & Silent Operation – Integrated silencers and smooth airflow

-

Durable & Long-Lasting – Premium carbon media and rugged housing

-

Low Maintenance – Minimal pressure drop and long carbon life

-

Customizable Solutions – Pressure, port size, and flow tailored to your system

Applications

-

Breathing Air Systems – Ensures clean, safe air for medical, diving, and safety applications

-

High-Pressure Laser Cutting – Delivers ultra-pure assist air for precision cutting

-

Pharmaceutical Cleanrooms – Removes oil vapor and odors from compressed air lines

-

Food & Beverage Packaging – Maintains taste and hygiene in high-pressure bottling systems

-

Electronic Component Manufacturing – Prevents contamination in high-purity environments

-

PET Blowing & Molding – Removes hydrocarbon vapors that may affect plastic integrity

-

General High-Pressure Air Systems – Where clean, oil-free compressed air is critical

High Pressure. Ultra Purity. Absolute Reliability.

Nitroxtec High Pressure Activated Carbon Tower Filters are your trusted solution for delivering Class 1 oil-free air in the most demanding pressure environments. Designed for long-term performance, low maintenance, and maximum safety, these towers protect your equipment, your processes, and your products—under pressure.