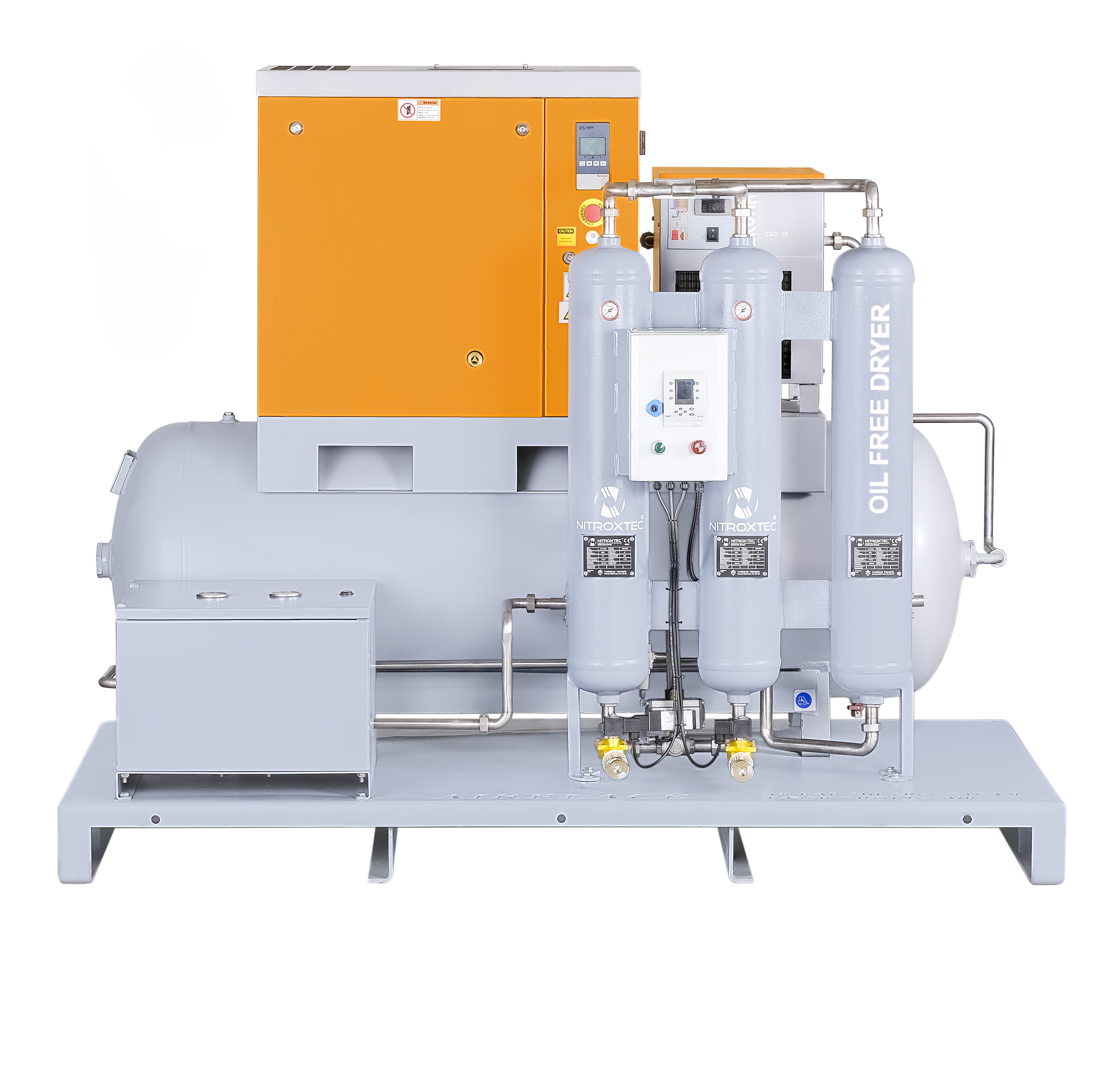

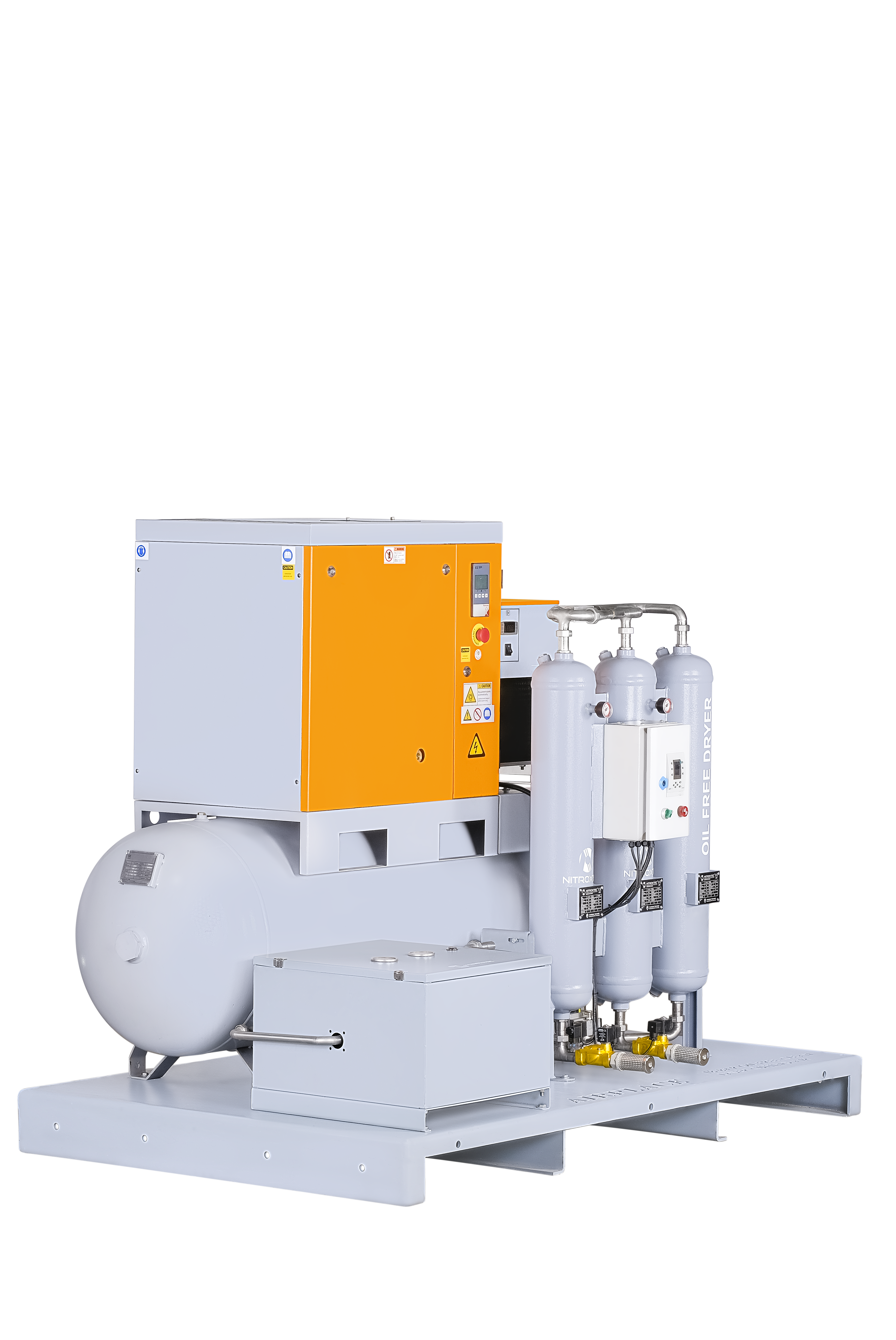

Airplace Air Cutting System (16–25 BAR)

High Pressure. Oil-Free. Optimized for Laser Cutting.

Nitroxtec Airplace is a high-efficiency compressed air solution developed for

fiber laser cutting machines.

Operating within a 13–25 BAR pressure range, it delivers

clean, dry, and oil-free air,

enabling precise, burr-free cutting of

carbon steel, galvanized steel, aluminum, DKP,

and similar materials.

Unlike traditional nitrogen or oxygen cutting methods,

Airplace eliminates the need for external gas supply when cutting

thin to medium thickness materials,

significantly reducing operational costs.

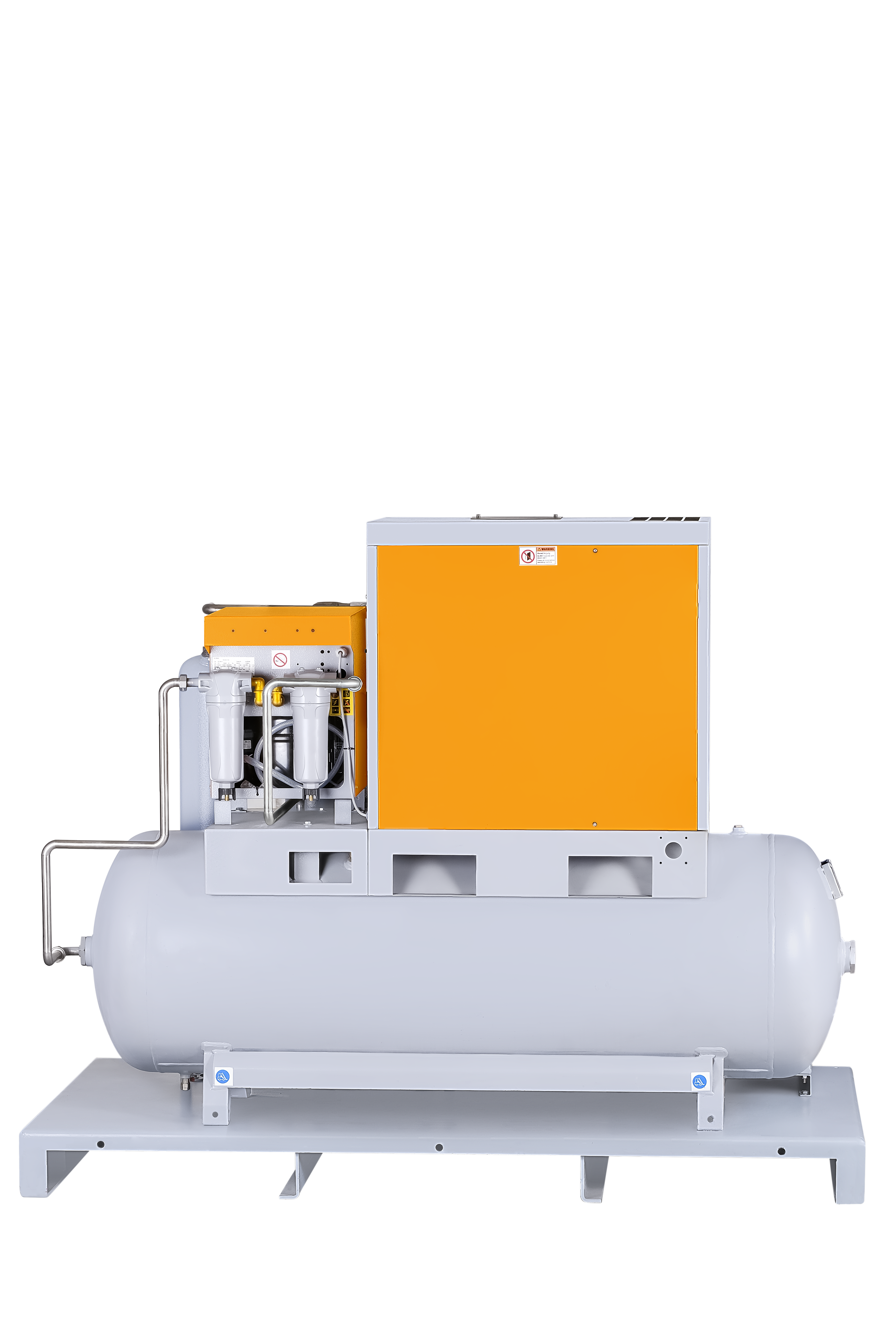

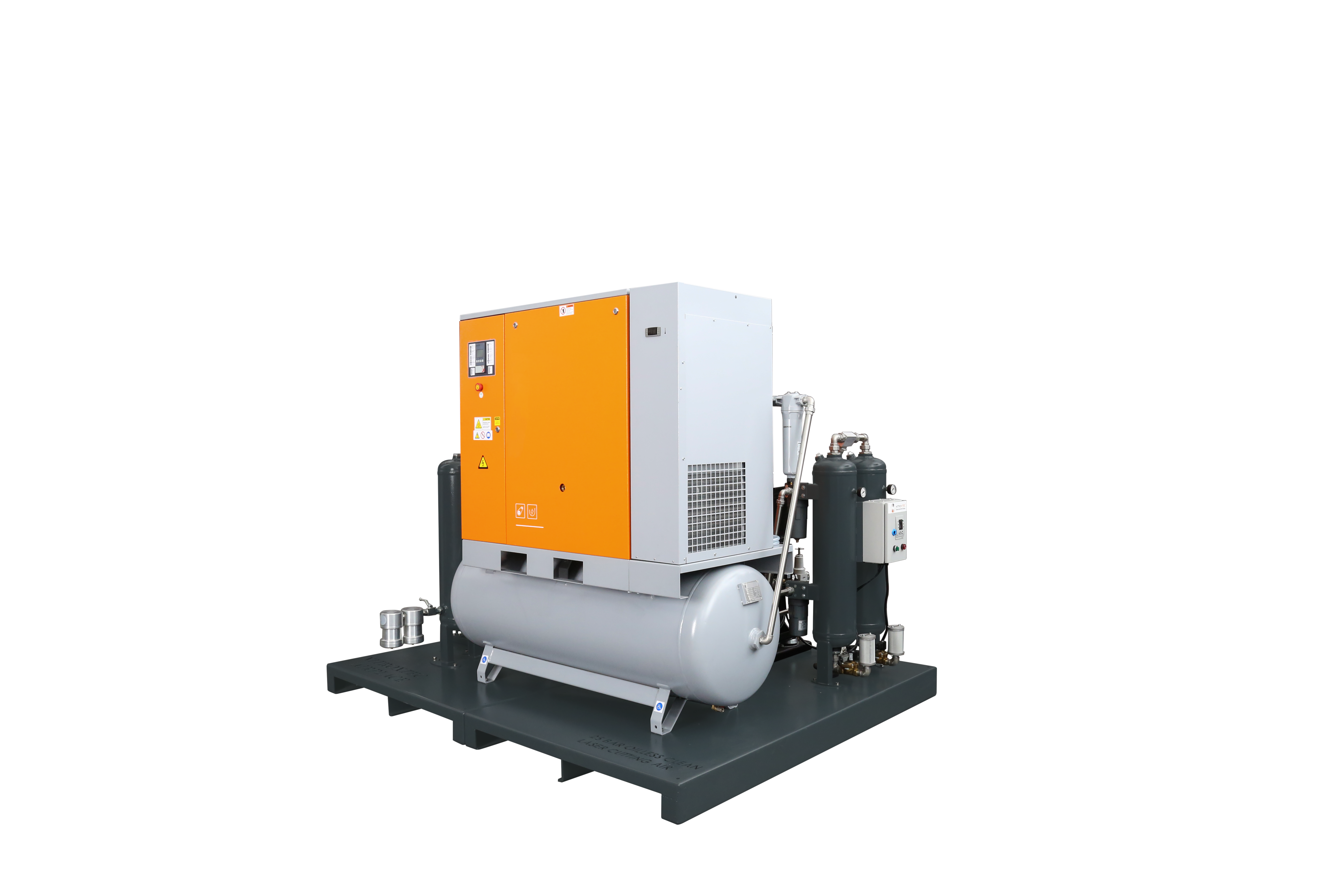

The integrated oil-free compressor,

filtration, and drying units

ensure air quality compliant with

ISO 8573-1:2010 standards.

Key Features

| Feature | Benefit |

|---|---|

| Oil-Free Compressed Air | Ensures high-quality cutting while protecting laser optics and lenses from contamination |

| High Pressure (13–25 BAR) | Provides consistent and stable pressure during cutting operations |

| Wide Material Compatibility | Suitable for carbon steel, aluminum, galvanized steel, and DKP sheets |

| Variable Cutting Thickness | Capable of cutting materials from 0.5 mm to 20 mm (depending on laser power and material) |

| Integrated Drying and Filtration | Removes oil and moisture — compliant with ISO 8573-1:2010 Class 2 air quality |

| Energy-Efficient Operation | Reduces energy consumption during continuous operation |

| Cost-Effective Solution | Eliminates nitrogen/oxygen supply costs for suitable cutting applications |

| Compact System Layout | Allows easy integration with existing laser cutting machine setups |

Applications

- Fiber Laser Cutting Machines

Why Choose Airplace?

Airplace offers a smart and economical alternative to traditional cutting gases

without compromising performance.

With oil-free compressor technology,

reliable pressure control,

and compliance with international air quality standards,

Nitroxtec delivers superior cutting efficiency,

clean operations, and long-term cost savings.