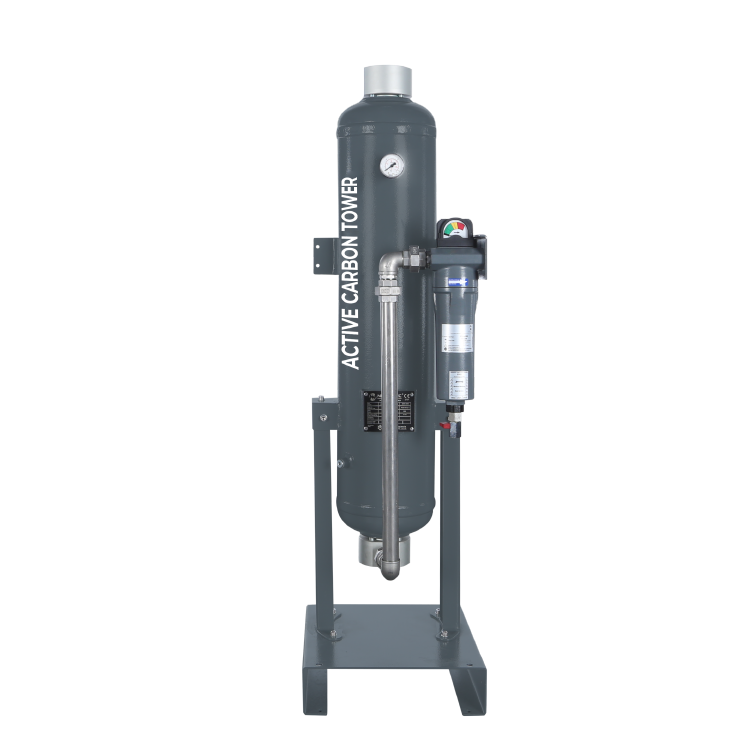

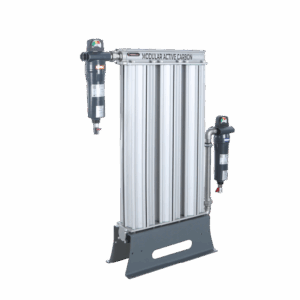

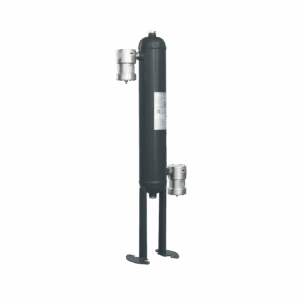

Activated Carbon Tower Filters

Oil-Free, Odor-Free Air for Critical Applications

Nitroxtec Activated Carbon Tower Filters are designed to ensure the highest level of air purity in compressed air systems by effectively removing residual oil vapors, hydrocarbons, and unwanted odors. Using premium-grade activated carbon media and an advanced flow distribution system, these towers deliver ultra-clean, odorless air for applications requiring ISO 8573-1:2010 Class 1 air quality.

What is Activated Carbon?

Activated carbon is a highly porous adsorbent material known for its exceptional capacity to trap oil vapor, organic compounds, and odors from air and gas streams. When compressed air passes through the carbon bed, hydrocarbons and oil vapors are adsorbed onto the internal surface of the activated carbon particles, resulting in purified, odor-free air.

To maintain consistent performance, Nitroxtec carbon towers are equipped with pre-filtration to remove bulk oil and particles before entering the adsorption bed, and optimized diffusers to ensure uniform airflow for maximum carbon efficiency.

Key Features

| Feature | Benefit |

|---|---|

| Residual Oil Vapor ≤ 0.003 mg/m³ | Meets ISO 8573-1:2010 Class 1 standard for critical purity. |

| Premium Activated Carbon Media | High-efficiency removal of oil vapors, hydrocarbons, and odors. |

| Integrated Pre-Filtration | European-grade oil and dust filters prevent bed contamination. |

| Quiet Operation | Silencer-equipped outlet for low-noise air discharge. |

| Automatic Drain Valves | Removes separated oil, water, and particulates automatically. |

| Optional Oil Indicator | Monitors oil levels for proactive maintenance. |

| Stable, Anchored Design | Rigid base for vibration-free industrial use. |

| Low Energy Consumption | Passive adsorption process ensures energy-efficient operation. |

| Operating Temperature: 1.5 °C – 50 °C | Suitable for a wide range of air systems. |

| Custom Pressure Models Available | Configurable for high-pressure applications upon request. |

Working Principle

Compressed air from the compressor first passes through a high-performance pre-filter that captures larger oil droplets and particles. It then flows uniformly through a specially designed diffuser into the activated carbon bed. As the air moves through the tower, oil vapor and hydrocarbons are adsorbed by the carbon media. The result is clean, odorless compressed air, discharged through a silenced outlet.

The automatic drain system removes condensed oil and moisture, while an optional oil indicator allows real-time monitoring of filter performance and saturation levels.

Why Choose Nitroxtec Activated Carbon Tower Filters?

-

ISO Class 1 Oil Purity – Delivers air with residual oil vapor ≤ 0.003 mg/m³

-

German-Grade Activated Carbon – Long-lasting and highly adsorptive

-

Low Maintenance – Minimal pressure drop and extended carbon life

-

Quiet & Clean Operation – Built-in silencers and drain valves

-

Customizable Designs – Available for various flow and pressure needs

-

Trusted in Sensitive Environments – Food, pharma, cleanrooms, and more

Applications

-

Pharmaceutical Production – Ensures sterile, oil-free compressed air

-

Food & Beverage – Prevents taste and odor contamination in packaging lines

-

Electronics & PCB Assembly – Protects sensitive components from oil vapor exposure

-

Paint & Coating Systems – Prevents defects caused by airborne hydrocarbons

-

Medical & Breathing Air Systems – Delivers high-purity air in life-critical applications

-

General Industry – Enhances air quality in any compressed air network requiring Class 1 output

Reliable Oil Vapor Removal. Odor-Free Air. Guaranteed Purity.

Nitroxtec Activated Carbon Tower Filters offer a robust, energy-efficient, and maintenance-friendly solution for achieving the cleanest possible compressed air. Designed for the most demanding air quality applications, these towers ensure your systems run safer, cleaner, and more reliably.