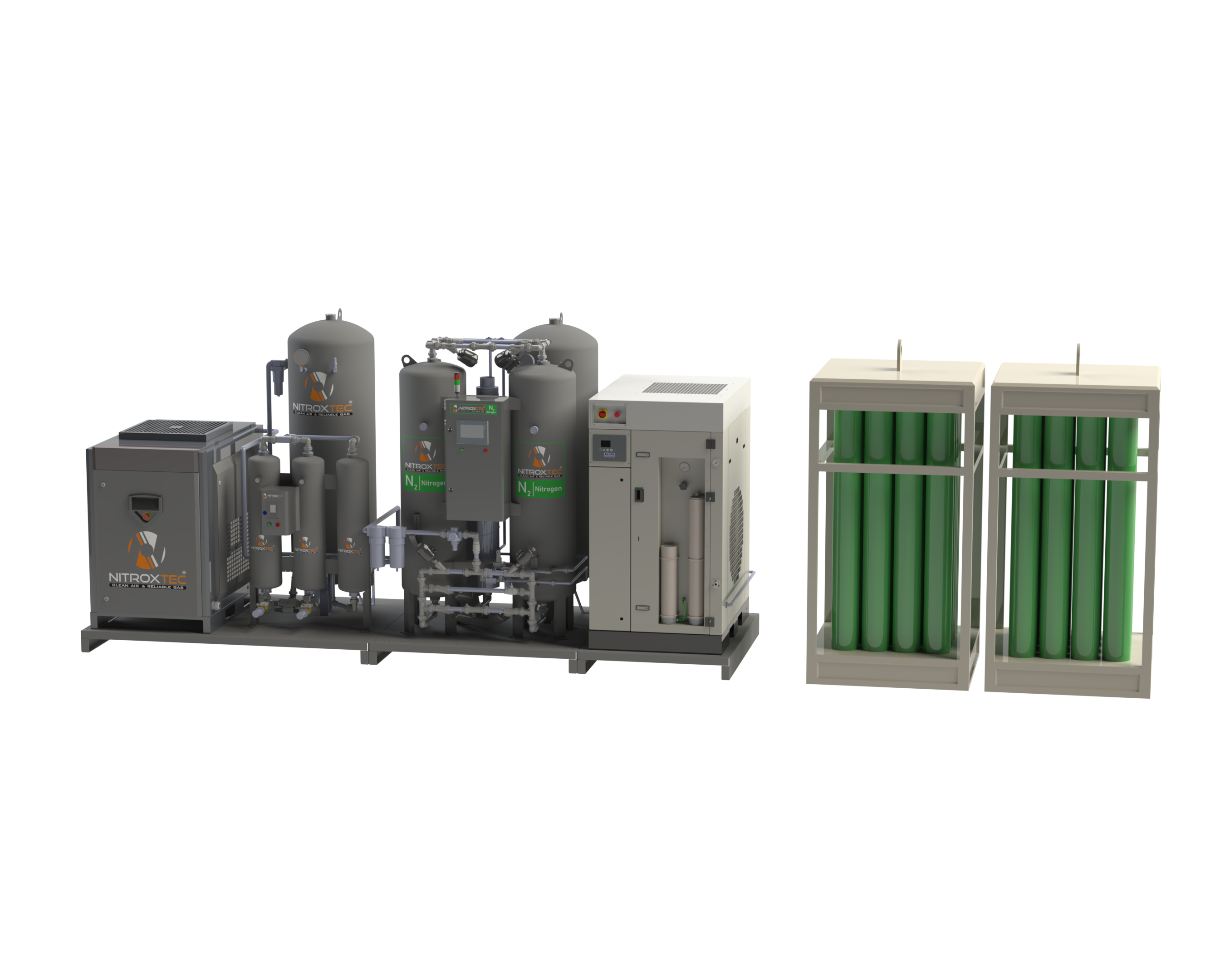

High-Purity Nitrogen Cutting Systems (230–300 BAR)

Ultra Pure. High Pressure. Designed for Laser Cutting.

Nitroxtec’s NITROPLACE system is a high-performance nitrogen generation and storage solution,

specifically designed for fiber laser cutting machines of 10 kW and above.

Operating within a 230–300 BAR pressure range, the system delivers

nitrogen purity levels of 99.99% to 99.999%, enabling

clean, oxidation-free cuts.

It is suitable for stainless steel, chrome, aluminum, copper, galvanized steel,

and other metals.

Unlike conventional gas supply methods, NITROPLACE produces and stores nitrogen on-site,

eliminating dependence on gas cylinders or liquid nitrogen.

This provides full independence, lower operating costs, and 24/7 operational reliability.

The system’s compact and modular design makes it suitable for both

single-machine installations and multi-line production facilities.

Key Features

| Feature | Benefit |

|---|---|

| Ultra-High Purity Nitrogen | 99.99% – 99.999% purity for clean, oxidation-free laser cutting |

| High-Pressure Delivery (230–300 BAR) | Provides stable gas flow for uninterrupted high-power cutting |

| Optimized for CO₂ and Fiber Laser Cutting | Designed for all laser cutting machine types |

| Energy Efficient | Consumes only 0.3 – 0.7 kWh of energy to produce 1 Nm³ of nitrogen |

| Full Metal Compatibility | Suitable for stainless steel, aluminum, chrome, galvanized steel, and other metals |

| On-Site Generation and Storage | Reduces operating costs and eliminates delivery delays |

| Compact, Scalable Design | Saves production space and adapts to future capacity expansion |

| Zero-Waste Production | No gas loss — produces only the amount you need |

Applications

- All Laser Cutting Machines

Why Choose NITROPLACE?

Nitroxtec’s NITROPLACE system gives manufacturers

full control over their nitrogen supply

through on-site production, ultra-high purity,

and high-pressure storage.

Without reliance on supply contracts or cylinder logistics,

it delivers a reliable, cost-effective,

and environmentally friendly nitrogen solution.

Compared to delivered gas, it offers up to 70% cost savings

and is specifically designed to meet the demands of today’s advanced laser cutting operations.