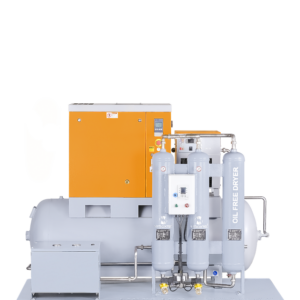

NitroMix Gas Cutting Systems (40 BAR)

Smart Cutting Gas. On Demand. Sustainable.

Nitroxtec’s NitroMix system is a next-generation mixed gas generation solution developed specifically for

fiber laser cutting machines of 10 kW and above. Operating within a

25–40 BAR pressure range, the system produces

nitrogen-based gas mixtures with adjustable purity between 95% and 99%.

This allows you to optimize cutting performance and cost efficiency according to your application.

By eliminating dependence on gas cylinders, long-term rental contracts, and external supply chains,

NitroMix delivers exceptional operational flexibility and cost control.

Its intelligent control system dynamically adjusts gas purity in real time,

ensuring precise, clean, and efficient results in

DKP, carbon steel, and galvanized steel.

Key Features

| Feature | Benefit |

|---|---|

| Adjustable Gas Purity (95–99%, 5–10% O₂) | Optimized for different materials and cutting thicknesses — reduces unnecessary costs |

| On-Site Mixed Gas Generation | Ensures fast and high-quality cutting for carbon and black steel |

| Energy & Cost Efficient | Produces only what is required — minimizes energy consumption and gas waste |

| High-Pressure Delivery (25–40 BAR) | Consistent performance across various laser cutting applications |

| No Cylinder Supply for Mixed Gas | Eliminates the need for separate nitrogen and oxygen cylinders |

| No Long-Term Contracts | Full independence from rental agreements and third-party pricing |

| Fixed Operating Costs | Protected against market fluctuations and gas price volatility |

| Compact System Integration | Space-saving design for seamless production integration |

| 24/7 Gas Availability | Continuous production without supply interruption risk |

Applications

- Fiber laser cutting machines (≥10 kW)

- High-speed, high-quality cutting for carbon steel

Why Choose NitroMix?

Nitroxtec’s NitroMix systems are smart, sustainable, and scalable.

With automatic purity adjustment and on-demand mixed gas generation,

NitroMix reduces costs while increasing cutting speed and precision.

It delivers reliable performance every shift and enables

cleaner operations, lower expenses, and uninterrupted productivity.